Liaoning Huawei Thermal Equipment Co., Ltd.

Address: 55 Anyang Street, Xiangyang Industrial Park, Liaoyang County, Liaoyang City, Liaoning Province

Tel: +86-0419-7677085

Website: www.lnhwrl.com

Website: en.lnhwrl.com

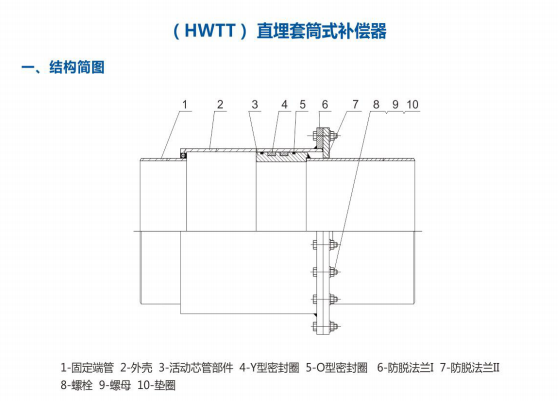

2. Compensation Principle of Sleeve Compensator

The working principle of sleeve compensator is to absorb the axial thermal displacement of thermodynamic pipeline by pushing the telescopic core pipe to move in a relative straight line along the pipeline axis in the sealed structure through the thermal expansion thrust of the thermodynamic pipeline, so as to release the thermal stress of the pipeline and ensure the safe operation of the pipeline, which is suitable for the auxiliary installation of the linear pipeline in the pipeline network.

3. Characteristics of Product Structure

1. Simple design, small size and easy installation.

2. High compensation capacity and low investment cost. It can be directly buried underground without the need for inspection wells.

3. The direct buried sleeve compensator is divided into two types: one-way sleeve compensator and two-way sleeve compensator. The two-way sleeve compensator is composed of two sets of movable core tube parts which are relatively installed. It can compensate the thermal deformation of the connecting pipes at both ends separately, and the compensating ability is greater.

3. Silicone rubber sealing material with good elasticity, high temperature resistance, corrosion resistance and aging resistance is adopted, which has long enough sealing surface length to ensure the reliable sealing of products.

4. The end of the core basket extending into the shell part is provided with a solid anti-detachment structure, which ensures that the product is more safe when it is stretched to the limit position.

5. Maintenance is convenient and can be carried out at any time with temperature and pressure under normal working conditions.

4. Sealing Principle and Manufacturing Technology of Sleeve Compensator

1. The direct-buried sleeve compensator adopts the advanced sealing principle of cylinder piston. It is sealed by multi-channel independent sealing chamber. O-type and Y-type silicone rubber sealing rings are placed in the chamber. The temperature range of silicone rubber rings is - 60 C - 225 C, and the hardness range is from Shaw's A25 to 90 C. And the sealed bed has

1) Reliable sealing performance

2) Small frictional resistance and smooth movement

3) It has good pressure resistance and wide pressure range.

4) Simple structure

5) Easy installation and other features

6) The sealing device is 0/YNY0 in the sealing chamber. The structure can ensure the sealing performance of the compensator in both static and pressurized operation states. (Type 0 sealing ring can ensure the sealing performance of compensator under static pressure and type Y sealing ring can guarantee the sealing performance under pressure operation. The higher the pressure, the larger the opening of Y sealing ring, the closer the lip and the two sealing surfaces are, the better the sealing performance is.)

2. The shell pipe thickness of the direct buried sleeve compensator is 1.5 times that of the base material of the pipeline, and the thickness of the movable core pipe component (sealing section) is not less than 30 mm. It can effectively improve the flexural strength and ellipticity change strength of the compensator, improve the concentricity of the connection between the compensator and the two sides of the pipeline, and prevent the influence of the sealing performance of the compensator caused by the settlement of the landfill layer and the self-weight of the medium in the pipeline, and effectively eliminate the influence of the sealing performance of the compe The possibility of leakage or dripping of the compensator.

3. The inner wall of the shell tube and the movable core tube parts (sealing section) of the direct-buried sleeve compensator are finely machined. The surface roughness of the fitting surface is 16um and polished. Hard chromium plating (non-decorative chromium) is carried out to improve the surface smoothness of the friction surface and reduce the friction resistance. The thickness of the chromium layer is not less than 4um and the corrosion resistance is longer than 30 years.

V. Installation Notes

1. Before installation, check whether the model and specifications of the felting compensator are in conformity with the design felting paper for pipeline construction, and the surface of the telescopic pipe is not damaged.

2. The installation position of the compensator in the pipeline should be installed according to the design requirements, and can not be adjusted at will. The distance between one side of the fixed end pipe of the one-way sleeve compensator and the fixed support of the pipeline should not be greater than 4 times the diameter of the pipeline, and the distance between the side of the telescopic pipe and the guide support should not be greater than 6 times the diameter of the pipeline, so as to reduce the deflection and deformation of the pipeline section.

3. Two-way sleeve compensator should be placed between two fixed supports in order to ensure equal compensation on both sides.

4. The medium flow direction of the pipeline should be in accordance with the compensation direction of the sleeve compensator, that is, the movable core pipe is the inlet and the fixed end pipe is the outlet.

5. Fixed bracket and sliding bracket should be set up according to the design stipulation. Guiding bracket should ensure free expansion of compensator during operation, and should not deviate from the pipeline.

6. Compensator and pipeline connection should be coaxial, coaxiality should be no more than 3 mm. The method of installing compensator is to connect the pipeline well first, then cut off the pipeline section equal to the length of compensator. It is strictly forbidden to adapt the deformation of compensator to the installation of deviating pipeline, so as to avoid affecting the normal work of compensator and increasing the load of supporting structure of pipeline equipment.

7. During installation, the compensator should strengthen the protection of telescopic core pipe components. Hardware should not scratch the metal surface. When the compensator and the pipeline are butt welded, arc initiation and wire lapping should not be carried out at the sliding part of the telescopic core pipe.

8. Remove the sand or dirt adhering to the surface of the expansion pipe in time. Make simple protection for the compensator before the temperature protection of the pipe. Do not expose it to prevent man-made touching, smashing and scratching. Thermal insulation materials should not hinder the normal work of the parts.

9. When installing and welding in cold season, preheating the welded parts should be carried out to prevent cold brittleness after welding.

10. Before the hydraulic test of the pipeline, the compensator must check whether the main and secondary fixing brackets are soldered firmly with the bearing members of the pipeline according to the design requirements. Whether the piecewise or integral pressure test is carried out, the beginning, end and corner of the pipeline should be effectively fixed to prevent the stress elongation from destroying the fixed point.

11. Compensators should be protected from collision during transportation, storage and installation. They should be stored in clean, dry and non-corrosive places.

![]()

Liaoning Huawei Thermal Equipment Co., Ltd.

Address: 55 Anyang Street, Xiangyang Industrial Park, Liaoyang County, Liaoyang City, Liaoning Province

Tel: +86-0419-7677085

Website: www.lnhwrl.com

|  |

| 【Mobile phone】 | 【WeChat】 |